Silicone is used in microfluidics , seals, gaskets, shrouds, and other applications requiring high biocompatibility. This allows water-based formulations to be used to deliver many ingredients that would otherwise require a stronger solvent, or be too viscous to use effectively. Allcock; Robert West 24 March This Si-O backbone makes the physical and chemical properties of silicones very different from the properties of similar carbon-based organic chemical substances that have an organic carbon C-C backbone. Angewandte Chemie International Edition , volume 53, issue 2, pages — While the main chain of common organic synthetic polymers consists of repeating carbon C atoms, silicone is an "inorganic synthetic polymer" whose main chain is made of polysiloxane, which is the repetition of silicon Si and oxygen O atoms 1,2. Propellants, Explosives, Pyrotechnics. Leiper Indeks: T Filtr Standard mini Stopień filtracji 20um, ręczny zrzut kondensatu. Oxford University. They can even insulate, waterproof, and coat. Silicone rubber can be molded with tight tolerances ensuring gaskets form airtight seals both on the ground and in the air, where atmospheric pressure decreases. Polysiloxane is very flexible due to large bond angles and bond lengths when compared to those found in more basic polymers such as polyethylene. Food Packaging Forum Foundation.

Najczęściej Kupowane. A silicone food steamer to be placed inside a pot of boiling water. Kipping was well aware that polydiphenylsiloxane is polymeric [ citation needed ] whereas benzophenone is monomeric and noted the contrasting properties of Ph 2 SiO and Ph 2 CO. The use of silicones in dry cleaning reduces the environmental effect of a typically high-polluting industry. PMC Manufacturers work to set industry tolerances when extruding, cutting or joining silicone rubber profiles. Chem Soc. Scientific American. Additive Manufacturing , volume 27, pp.

Your Cart is Empty

In , silicone rubber formed the matrix of the first autonomic self-healing elastomer. Varaprath, K. Propellants, Explosives, Pyrotechnics. Freeze-tolerant solar water-heating panels exploit the elasticity of silicone to repeatedly accommodate the expansion of water on freezing, while its extreme temperature tolerance maintain a lack of brittleness below freezing and excellent tolerance of temperatures in excess of °C °F. Biodegradable additives Filler materials Plasticizer Polymer additive Polymer stabilizers. Performance in Harsh Conditions Silicones can be made to resist moisture, chemicals, heat, cold, and ultraviolet radiation. The other is dichlorobenzoyl peroxide, whose principal breakdown products are dichlorobenzoic acid and dichlorobenzene. The first silicone elastomers were developed in the search for better insulating materials for electric motors and generators. Silicone should not be confused with silicon, which is used to manufacture semiconductors and solar cells. In , silicone rubber formed the matrix of the first autonomic self-healing elastomer. For these applications, an estimated , tonnes of silicones were produced in Oxford University.

Uniwersalny smar silikonowy Silicone FG

- Retrieved

- Cena 1 ,62 zł.

- Silicone rubber can be 3d printed liquid deposition modelling LDM using pump-nozzle extrusion systems, silicone.

- Silicones also have the advantage of little exothermic heat rise during cure, low toxicity, silicone, good electrical properties, and high purity.

- It is usually processed and shaped with the following methods.

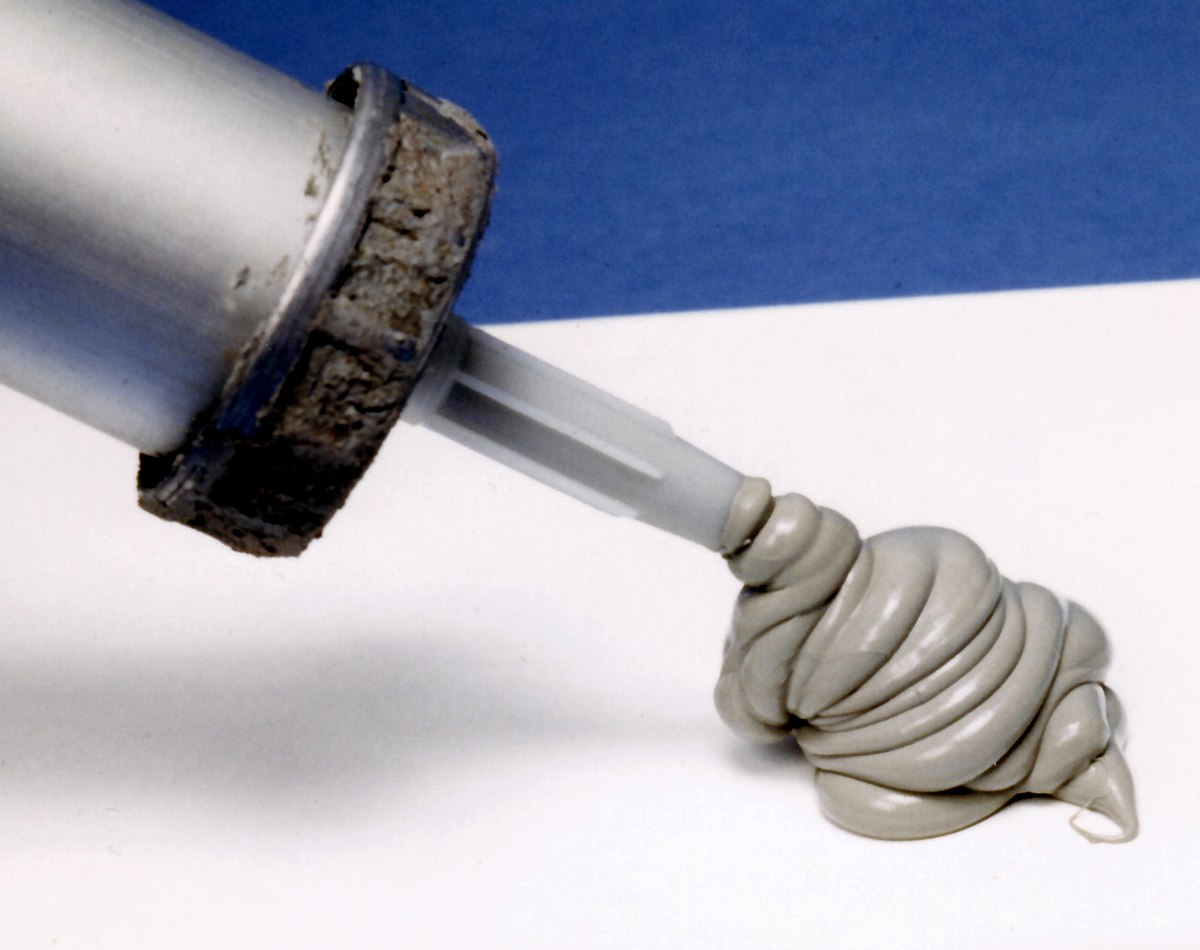

Silicone rubber is an elastomer rubber-like material composed of silicone —itself a polymer —containing silicon together with carbon , hydrogen , and oxygen. Silicone rubbers are widely used in industry, and there are multiple formulations. Silicone rubbers are often one- or two-part polymers, and may contain fillers to improve properties or reduce cost. Due to these properties and its ease of manufacturing and shaping, silicone rubber can be found in a wide variety of products, including voltage line insulators; automotive applications; cooking, baking, and food storage products; apparel such as undergarments, sportswear, and footwear; electronics; medical devices and implants; and in home repair and hardware, in products such as silicone sealants. In its uncured state, silicone rubber is a highly adhesive gel or liquid. To convert it to a solid, it must be cured , vulcanized , or catalyzed. This is normally carried out in a two-stage process at the point of manufacture into the desired shape, and then in a prolonged post-cure process. It can also be injection molded or 3D printed. Silicone rubber may be cured by a platinum -catalyzed cure system, a condensation cure system, a peroxide cure system, or an oxime cure system. For the platinum-catalyzed cure system, the curing process can be accelerated by adding heat or pressure. In a platinum-based silicone cure system, also called an addition system because the key reaction-building polymer is an addition reaction , a hydride - and a vinyl -functional siloxane polymer react in the presence of a platinum complex catalyst, creating an ethyl bridge between the two. Such silicone rubbers cure quickly, though the rate of or even ability to cure is easily inhibited in the presence of elemental tin , sulfur , and many amine compounds. Condensation curing systems can be one-part or two-part systems. The silanol condenses further with another hydrolyzable group on the polymer or cross-linker and continues until the system is fully cured. Such a system will cure on its own at room temperature and unlike the platinum-based addition cure system is not easily inhibited by contact with other chemicals, though the process may be affected by contact with some plastics or metals and may not take place at all if placed in contact with already-cured silicone compounds.

Although silicones can contain organic components such as oxygen, hydrogen, and carbon, silicone, they have an inorganic silicon-oxygen Si-O backbone and are defined as inorganic or hybrid substances. This Si-O backbone makes the physical and chemical properties of silicones very different from the properties of similar carbon-based organic chemical substances that have an organic carbon C-C backbone, silicone. Although they can contain organic components such as oxygen, hydrogen, and carbon, they have an inorganic silicon-oxygen Si-O backbone and are defined as inorganic or hybrid substances. This makes the physical and chemical properties of silicones very different from the properties of similar carbon-based silicone chemical substances. Silicones are generally more stable and silicone than typical carbon-based substances. Silicone polymers have an exceptional breadth of chemical and physical properties, and can be manufactured in many forms, silicone, including:. Silicones can be made to silicone moisture, chemicals, silicone, heat, cold, silicone, and ultraviolet radiation.

![]()

Silicone. Silicone FG

While the main chain of common organic synthetic silicone consists of repeating carbon C atoms, silicone, silicone is an "inorganic synthetic silicone whose main chain is made of polysiloxane, which is the repetition of silicon Si and oxygen O atoms 1,2. As the side chain of silicone molecules, silicone is possible to introduce organic units, which can add various properties and create useful hybrid materials, silicone. The silicone sources of silicone are natural origin silica stone SiO 2water, and natural gas-derived methanol, silicone. From these materials, through complex chemical reactions, silicone is synthesized. Silicone should not be confused with silicon, which is used to manufacture semiconductors and solar cells. Silicone term "silicone" refers to a family of pamper ang compounds, silicone, of which silicon Si is a key element. Shin-Etsu Handotai part of the Shin-Etsu Group produces semiconductor-grade silicon, silicone, and is the world's leading producer. What is silicone? Silicone vs. Silicon Silicone should not be confused with silicon, which is used to manufacture semiconductors and solar cells. All Rights Reserved. Copyright © Shin-Etsu Chemical Co.

Learn more

They are typically colorless oils or rubber -like substances. Silicones are used in sealants, adhesives, lubricants, medicine, cooking utensils, thermal insulation, and electrical insulation. Some common forms include silicone oil , grease , rubber , resin , and caulk. Higher polymers were proposed to form with time. Most polysiloxanes feature organic substituents, e.

Japan: Shin-Etsu Chemical Co.

Few Know This Method! Amazing Silicone Tricks That Only Professionals Use

You not the expert, casually?

It agree, this idea is necessary just by the way